Babban dutse

Fage

Ana san dutsen kai da sunaye daban-daban, kamar su duwatsun tunawa, alamomin kabari, duwatsun kabari, da duwatsun kabari.Duk waɗannan sun shafi aikin dutsen kai;da tunawa da tunawa da mamaci.Asalin duwatsu an yi su ne daga duwatsun gona ko guntun itace.A wasu yankuna, an sanya duwatsu (wanda ake kira “dutsen wolf”) a jikin jiki don hana ɓarna dabbobi daga fallasa wani kabari mara zurfi.

Tarihi

Masu binciken kayan tarihi sun gano kaburburan Neanderthal da suka yi shekaru 20,000-75,000.An gano gawarwakin a cikin koguna masu manyan tulin duwatsu ko duwatsun da ke rufe wuraren budewa.Ana tsammanin waɗannan wuraren kaburbura sun kasance cikin haɗari.An bar wadanda suka jikkata ko wadanda suka mutu a baya don su warke, kuma an tura duwatsu ko duwatsu a gaban kogon domin kariya daga namun daji.Kogon Sharindar da ke Iraki gida ne ga gawar wani mutum (kimanin 50,000 BC) tare da furanni da aka baje a jikin.

Wasu hanyoyin binnewa daban-daban sun samo asali yayin da lokaci ya ci gaba.Sinawa su ne na farko da suka yi amfani da akwatunan gawarwaki wajen dauke da gawarwakinsu a wani lokaci kimanin shekara 30,000 kafin haihuwar Annabi Isa, an yi amfani da gawarwakin gawa da kawanya a shekara ta 3200 BC don adana gawarwakin Fir'aunan Masar har lahira.Za a sanya fir'auna a cikin sarcophagus kuma a lulluɓe su da mutummutumai masu wakiltar bayinsu da amintattun mashawarta, da zinariya da kayan alatu don tabbatar da karɓunsu a bayan duniya.Wasu sarakuna sun bukaci bayinsu da mashawarta na ainihi su raka su mutuwa, kuma aka kashe bayi da masu ba da shawara aka sanya su a cikin kabari.Yin kone-kone, wanda ya fara kusan lokaci guda da gamuwa, kuma sanannen hanyar zubar da matattu ne.A yau yana da kashi 26% na hanyoyin zubarwa a Amurka da 45% a Kanada.

Yayin da addinan suka ci gaba, ana raina konewa.Addinai da yawa ma sun hana kona konewa, suna da’awar cewa hakan yana tunawa da al’adun arna.Hanyar da aka fi so a binne matattu ne, kuma a wasu lokuta ana ajiye matattu na kwanaki a cikin gida don mutane su iya girmama su.A shekara ta 1348, annoba ta afkawa Turai kuma ta tilasta wa mutane su binne matattu da wuri-wuri kuma daga garuruwa.Ana ci gaba da gudanar da waxannan ibadodi na mutuwa da binnewa har maqabartu suka cika, kuma saboda yawan kaburbura, suka ci gaba da yaxuwa cututtuka.A shekara ta 1665, majalisar dokokin Ingila ta yanke hukunci don samun ƙananan jana'izar kawai kuma an sanya zurfin kaburbura ya tsaya a 6 ft (1.8 m).Wannan ya rage yaduwar cututtuka, amma yawancin makabartu sun ci gaba da yin yawa.

Kabari na farko mai kama da wanda aka gani a yau, an kafa shi a birnin Paris a shekara ta 1804 kuma ana kiransa makabartar "lambu".Pèere-Lachaise gida ne ga shahararrun sunaye kamar Oscar Wilde, Frederick Chopin, da Jim Morrison.A cikin waɗannan kaburbura na lambun ne dutsen dutse da abubuwan tunawa suka zama ayyuka na musamman.Matsayin zamantakewar mutum ya ƙayyade girman da fasaha na abin tunawa.Tunawa da farko sun nuna munanan al'amuran tare da kwarangwal da aljanu don sanya tsoron lahira a cikin masu rai.Daga baya a cikin karni na sha tara, duwatsun kanana sun samo asali don neman yanayin kwanciyar hankali, kamar su kerubobi da mala'iku suna ja-gorar mamaci zuwa sama.{Asar Amirka ta kafa nata makabartar karkara, The Mount Auburn Cemetery a Cambridge, Massachusetts, a 1831.

Raw Materials

An yi manyan duwatsu na farko daga slate, wanda ake samu a gida a farkon New England.Abu na gaba da ya zama sananne shine marmara, amma bayan lokaci dutsen marmara zai ɓace kuma ba a iya tantance sunaye da bayanan mamacin.A shekara ta 1850, granite ya zama abin da aka fi so saboda juriyarsa da samun damarsa.A cikin abubuwan tunawa na zamani granite shine babban kayan da ake amfani dashi.

Granite dutse ne mai banƙyama wanda aka haɗa da farko na quartz, feldspar, da plagioclase feldspar tare da wasu ƙananan ma'adanai waɗanda aka haɗe a ciki. Granite na iya zama fari, ruwan hoda, launin toka mai haske, ko launin toka mai duhu.Ana yin wannan dutse daga magma (narkakken abu) wanda a hankali ake sanyaya.Ana gano magma da aka sanyaya ta hanyar sauye-sauye a cikin ɓawon ƙasa da zaizayar ƙasa.

Zane

Akwai hanyoyi marasa adadi don keɓance babban dutse.Epitaphs sun fito ne daga maganganun nassi zuwa maganganun da ba a sani ba da ban dariya.Ana iya sassaƙa gumaka masu rakiyar a ciki, a sanya su a saman, ko a gefen dutsen.Girma da siffar manyan duwatsu suma sun bambanta.Gabaɗaya, duk duwatsu ana goge su da na'ura da sassaƙa, sa'an nan dalla-dalla da hannu.

The Manufacturing

Tsari

- Mataki na farko shine zaɓi nau'in (yawanci marmara ko granite) da launi na dutse.Sa'an nan kuma an yanke shingen granite daga bene.Akwai hanyoyi guda uku na yin wannan.Hanya ta farko ita ce hakowa.Wannan hanyar tana amfani da rawar motsa jiki mai huhu wanda ke ɗauke da ramukan tsaye 1 a (2.54 cm) baya da 20 ft (6.1m) zurfi cikin dutsen dutse.Masu fasa dutsen sai su yi amfani da guntun karfe 4 in (cm 10.1) masu tsayi masu haƙoran ƙarfe don yanke su a tsakiyar dutsen.

Sojin jet yana da sauri fiye da hakowa, kusan sau bakwai haka.A cikin wannan hanya, 16 ft (4.9 m) za a iya rushewa a cikin sa'a daya.Tsarin yana amfani da motar roka tare da ramin karfe don korar gauran man fetur na hydrocarbon da aka matsa da iska a cikin nau'in harshen wuta 2,800°F (1,537.8°C).Wannan harshen wuta ya ninka saurin sauti sau biyar kuma yana yanke 4 in (cm 10.2) cikin granite.

Hanya ta uku ita ce hanya mafi inganci, mafi shuru, kuma ba ta haifar da ɓata kusan ba.Huda jet na ruwa yana amfani da matsa lamba na ruwa don yanke granite.Akwai tsarin guda biyu na huda jet na ruwa, ƙananan matsa lamba da matsa lamba.Dukansu suna fitar da rafukan ruwa guda biyu, amma ƙananan tsarin tsarin magudanar ruwa suna ƙarƙashin 1,400-1,800 psi, kuma manyan magudanan ruwa suna ƙarƙashin 40,000 psi.Ana sake amfani da ruwa daga jets, kuma hanyar ta rage kurakurai da kayan da aka ɓata.

- Mataki na gaba shine cire shingen daga gadon dutse.Ma'aikata suna ɗaukar manyan atisayen huhu da 1.5-1.88 a cikin (3.81-4.78 cm) na ƙarfe da aka haɗe tare da carbide kuma suna yin rawar jiki a kwance cikin shingen granite.Sannan suna sanya cajin fashewar fashewar takarda a cikin ramukan.Da zarar an saita cajin, toshe yana yin hutu mai tsabta daga sauran dutsen.

- Tubalan Granite yawanci kusan 3 ft (0.9 m) faɗi, 3 ft (0.9m) tsayi, da tsayi 10 ft (3 m), suna yin awo kusan 20,250 lb (9,185 kg).Ma'aikata ko dai sun madauki kebul a kusa da shingen ko kuma su yi ƙugiya zuwa kowane ƙarshen kuma su haɗa kebul ɗin zuwa ƙugiya.A cikin hanyoyi guda biyu an haɗa kebul ɗin zuwa wani babban derrick wanda ke ɗaga shingen granite sama da kan wata babbar motar da ke ɗauke da ita zuwa ga masana'anta.Kamfanonin sun kasance mallakar kansu ne kuma suna siyar da granite ga masana'antun, amma akwai wasu manyan kamfanoni waɗanda suka mallaki katafaren gini.

- Bayan isowa gidan masana'anta, ana sauke ginshiƙan dutsen a kan bel ɗin jigilar kaya inda aka yanke su cikin ƙananan tudu.Tsakanin suna gabaɗaya 6, 8, 10, ko 12 in (15.2, 20.3, 25, da 30.4 cm, bi da bi).Ana yin wannan matakin tare da zato na lu'u-lu'u.Sanye take da fensir 5 ft (1.5m) ko 11.6 ft (3.54 m) tsayayyen ruwan lu'u-lu'u.Ruwa yawanci yana da kusan sassan lu'u-lu'u na masana'antu 140-160 kuma yana da ikon yanke matsakaicin 23-25 ft.2(2.1-2.3 m2) awa daya.

- Ana wuce sassan da aka yanke a ƙarƙashin adadin daban-daban masu juyawa (yawanci takwas zuwa 13) tare da matakan grit daban-daban.

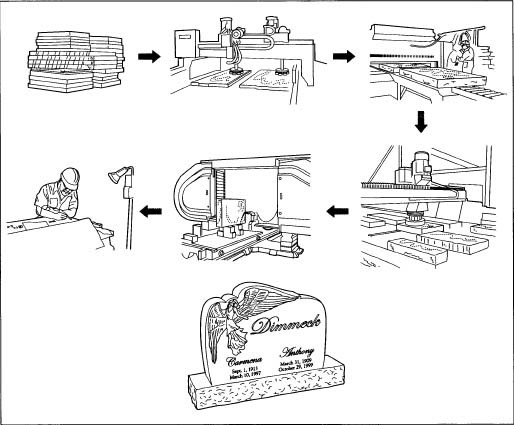

Samar da dutsen kai.

daga mafi ƙasƙanci zuwa ƙarami.Kaɗan na farko suna da lu'u lu'u-lu'u masu tsauri, kawunan na tsakiya don yin honing ne, kuma 'yan na ƙarshe suna da sanye take da faifan maɓalli.Waɗannan pads ɗin suna da ruwa da aluminium ko foda na tin oxide akan su don goge dutsen zuwa ga santsi mai kyalli.

- Sa'an nan kuma a matsar da bel ɗin da aka goge tare da bel ɗin jigilar kaya zuwa na'urar hydraulic.Mai karyawa yana sanye da haƙoran carbide waɗanda ke yin kusan psi 5,000 na matsa lamba na hydraulic a kan dutsen granite, yana yanke dutsen a tsaye.

- Dutsen da aka yanke sai an yi shi a cikin siffar da ta dace.Ana yin wannan da hannu tare da guntu da guduma, ko kuma daidai da abin zato na lu'u-lu'u.Ana iya saita wannan na'ura don ɗaukar ruwan sama 30, amma yawanci ana loda shi da takwas ko tara kawai.An sanye shi da ruwan wukake guda tara, wannan ma'aunin lu'u-lu'u da yawa na iya yanke ƙafa 272(2.5m2) awa daya.

- Ana sake goge saman dutsen.A cikin tsari mai sarrafa kansa sosai, ana iya goge guda 64 a lokaci guda.

- Ana goge gefuna na tsaye ta na'ura mai sarrafa kansa, mai kama da polisher na saman.Wannan injin yana zaɓar kan mafi ƙanƙanta kuma yana aiki da shi a saman gefuna na dutse a tsaye.Sannan injin yana aiki ta hanyar sauran grits har sai gefuna sun yi santsi.

- Gefen radial suna ƙasa kuma an goge su a lokaci guda ta amfani da ganguna masu niƙa guda biyu na lu'u-lu'u.Ɗayan yana da lu'u-lu'u mai tsauri, kuma na biyu yana da mafi kyawun grit.Ana goge gefuna na radial na dutse.

- Idan ana buƙatar sifofin dutse masu rikitarwa, ana motsa dutsen da aka goge zuwa ma'aunin waya na lu'u-lu'u.Mai aiki yana daidaita zato kuma ya fara aikin, wanda ke amfani da software na kwamfuta don daidaita sifofi zuwa dutsen kai.Duk wani kyakkyawan etching ko cikakken bayani an gama shi da hannu.

- An shirya babban dutse don kammalawa.Rock Pitching ya haɗa da yanke gefen dutsen da hannu, yana ba da ƙarin ma'ana, siffar mutum.

- Yanzu da aka goge dutsen O da siffa, lokaci yayi da za a sassaƙa.Gabaɗaya ana amfani da fashewar yashi.Ana shafa manne ruwa a kan dutsen kai.Ana amfani da stencil na roba akan manne sannan kuma an rufe shi da tsarin ƙira mai goyan bayan carbon.Carbon yana jujjuya ƙirar da mai zane ya shirya, zuwa kan stencil na roba.Sa'an nan ma'aikacin ya yanke haruffa da siffofi na zane da ake so a kan dutse, yana nuna su ga fashewar yashi.Ana yin yashi ko dai da hannu ko kuma ta atomatik.Ko wace hanya ana yin ta ne a cikin wani yanki da ke kewaye saboda haɗarin tsarin.An rufe ma'aikaci gaba ɗaya don a kare shi daga hatsin da aka nuna a kan dutse.Ana aiwatar da aikin yanke abrasive akan ƙarfin 100 psi.Masu tara ƙura suna tattarawa da ajiye ƙurar don sake amfani da su.

- Ana fesa dutsen da tururi mai ƙarfi don kawar da duk wani abin da ya rage ko kuma manne.An sake goge shi kuma an duba shi sosai, sannan an shirya shi a cikin cellophane ko takarda mai nauyi don kare ƙarewa.Ana sanya kunshin a cikin akwatuna kuma a aika zuwa abokin ciniki ko darektan jana'izar.

Kula da inganci

Ana aiwatar da sarrafa inganci da ƙarfi a cikin tsarin masana'antu.Ana duba kowane shinge na granite mai kauri don daidaiton launi.Bayan kowane mataki na gogewa, ana bincika dutsen kan don kurakurai.A farkon alamar guntu ko karce, an cire dutsen daga layin.

Samfuran / Sharar gida

Ya danganta da tsarin yankan da ake amfani da shi a wurin kwalta, sharar gida ta bambanta.Hakowa ita ce hanya mafi ƙarancin madaidaicin hanyar fasa dutse, don haka yana samar da mafi yawan sharar gida.Hanyar jet na ruwa yana samar da mafi ƙarancin gurɓataccen amo da ƙura.Har ila yau, ya fi sauran hanyoyin sarrafa mai, kuma yana ba da damar sake sarrafa ruwa.A cikin fashewar yashi kuma akwai ɓata kaɗan tunda ana tattara ɓangarorin yashi kuma ana sake amfani da su.Duk wani lahani na dutsen granite daga masana'anta ana sayar da su gabaɗaya ga wasu kamfanonin masana'antu ko fitar da su zuwa ketare.Ana zubar da sauran duwatsu marasa inganci.

Gaba

Akwai sabbin dabaru da yawa waɗanda ke amfani da sabbin software don tsara ƙira akan dutsen kai.Laser etching wani ci gaba ne mai zuwa wanda ke ba da damar hotuna da ƙarin ƙira masu rikitarwa don sanya su a kan dutsen kai ta amfani da katako na Laser.Zafin Laser yana fitar da lu'ulu'u a saman dutsen granite, wanda ya haifar da haɓaka mai girma, etching mai launin haske.

Ragewar granite ba a iya gani a nan gaba.Yayin da ake hako ma'adanai, sabbin albarkatu suna haɓaka.Akwai ƙa'idodi da yawa waɗanda ke iyakance adadin granite wanda za'a iya fitar dashi a lokaci guda.Madadin hanyoyin zubar da matattu kuma abubuwa ne da ka iya takaita samar da duwatsun kai.

Lokacin aikawa: Janairu-05-2021